Next Generation Passport Issuance Is Accelerating

|

NEWS

|

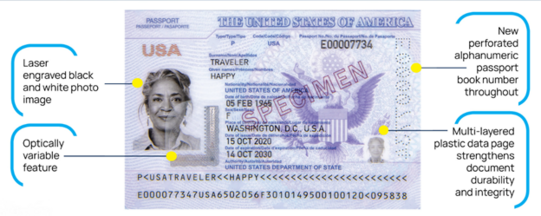

The next generation of U.S. passports began rolling out in 2021 and that trend will continue going forward. Compared to the 28 pages found in a standard ePassport, the Next Generation Passport has just 26 pages; the expanded book of the new iteration has 2 pages less than the standard ePassport, bringing the total number of pages down to 50. The book number can be located at the top right-hand corner of the datapage and at the bottom of every other page in the book.

To understand the motivation behind issuing Next Generation Passports and transitioning to a new U.S. passport design, a State Department official shared this insight with AFAR: “The Next Generation Passport uses new technologies to produce a more robust passport with enhanced security features, such as a Polycarbonate (PC) datapage, laser engraved personalization and updated artwork.” Everything about the new U.S. passport design ties back to providing U.S. citizens with improved safety and personalization from the previous generation.

Figure 1: Photo of what a Next Generation Passport looks like (Source: U.S. State Department)

The Benefits of the New U.S. Passport Design

|

IMPACT

|

The key difference between the Next Generation Passport and its predecessor is the material and design of the datapage, which is now being constructed of polycarbonate. This yields a significant enhancement to security, which can be considered the main driver for migrating to this datapage type. Like all PC passport structures, the new U.S. passport design is monolithic, as opposed to the layered plastic of a Polyvinyl Chloride (PVC) document, which gives the Next Generation Passport considerable resistance to tampering by delamination. The use of polycarbonate material opens the door to more robust personalization procedures. PC datapages facilitate advanced security features like Multiple Laser Images (MLIs), Changeable Laser Images (CLIs), holograms, and tactile features. As well as providing increased security, these features enable document checks to be easily verified with minimal training, while remaining compliant with time-sensitive applications.

Further to the advanced personalization features of the Next Generation Passport facilitated by PC is laser engraving. Not only is laser engraving more secure from a physical security perspective, but it also lowers personalization costs per unit when mass-produced in a centralized facility. Considering the large volume of Next Generation Passports that will eventually be in circulation, alongside the negated additional costs from increased document security, PC adoption is cost-effective, despite the cost of individual PC credentials being high. Additionally, greater security will pave the way for more streamlined entry and exit processes in airports, enhancing citizen experience and easing airport operations.

Moreover, PC has a well-established reputation as being a more durable material than PVC or paper. This furthers the cost-effectiveness of the transition to the Next Generation Passport, as the passport is less likely to need replacements, also being beneficial to citizens whose passports are now more robust. This is advantageous from a sustainability perspective, too, as the decreased replacement rate is in line with growing environmental concerns and the related corporate social responsibility. Furthermore, aside from replacement, the material itself is far less harmful to the environment than alternatives, such as PVC. The use of hydrocarbons and minimal controlled chemicals in PC production creates only water and carbon dioxide as byproducts. This differs from the case of some alternative materials, which create toxic gases that are harmful to the environment. The alignment of the movement to PC for the Next Generation Passport with sustainability practices again places the transition in a positive light and gives reason to fuel PC documentation adoption in a wider sense.

Next Generation Passport Forecasts vs Other Regions

|

RECOMMENDATIONS

|

The introduction of the Next Generation Passport follows the global trend and increasing appetite for polycarbonate migration in general. The new U.S. passport design is consistent with what much of the world has already been savvy to. PC passports are already embraced by many countries globally, with 104 million PC passports being shipped in 2022, according to ABI Research’s Passports and Polycarbonate: Securing the Datapage research analysis report. While Europe’s 96% PC passport penetration rate is impressive, even more, impressive is the instantaneous turnaround of US passport development—where 100% of U.S. passports will be made of polycarbonate by the end of 2023 after being 0% in 2020. In the Asia-Pacific region, where the greatest quantity of total passports is issued annually, there will only be a 42% PC penetration rate of newly issued passports in 2025 (still amounting to 41 million PC passport shipments in that year). Overall, the global PC passport penetration rate is 55% in 2022, and by 2025, that number will increase to 62%.

This growing migration must be recognized, especially in consideration of the United States making this transition as a major global influencer. Card vendors, personalization vendors, and governments should be prepared as the ID space sees increasing demand for PC documents. Whether this is in developing new solution offerings, discontinuing products that don’t align with global trends, or preparation by other means, the readiness and capability to deal with this change in the market is an important strategic consideration.