Nearly 45,000 people and 900 exhibitors signed up for Automate, the largest robotics and automation trade show in North America, held in Chicago May 6-9, 2024. As a show, Automate is more focused than Hannover Messe or IMTS and, consequently, there were many automation and tooling suppliers, including ABB, Atlas Copco, and FANUC that chose this event over its larger peers.

European events like Hannover Messe also clearly evidence regional influences such as lots of sustainability messaging and hydrogen-fueled clean energy examples. Automate, by contrast, had little messaging around sustainability and zero notable hydrogen demos from companies that had a presence at both events—most notably Festo, Siemens, Beckhoff, Phoenix Contact, and TeamViewer.

Figure 1: Festo on the Show Floor

(Source: ABI Research)

Vendor Focus Points

Interestingly, some suppliers, like Beckhoff, elected to show a generative Artificial Intelligence (AI) demo at the last two Hannover Messe events, but did not have any generative AI examples in the booth at Automate. Siemens was more consistent, showing arguably the most comprehensive set of innovations in the form of both end-to-end and composable offerings.

Besides pure-play robotics and automation, there was a focus on peripheral islands that support automation—quality comes to mind, in addition to the surrounding automation software ecosystem. Quality providers including Cognex, Keyence, and Nikon were on the fringes of the expo floor amid rows of industrial automation and AI/Deep Learning (DL) software suppliers such as Inductive Automation and Neurala, respectively.

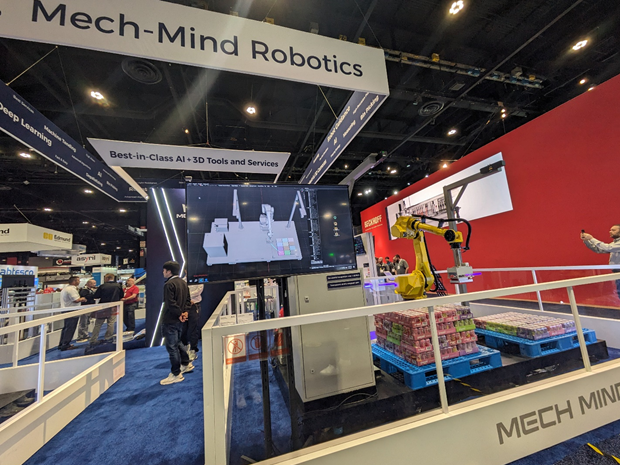

Machine Vision (MV) hardware was more prominently on display at the expo entrance via Zebra (acquired Matrox Imaging in 2022) and Mech-Mind, an Intel capital-backed Chinese company with growing global operations.

Figure 2: Mech-Minded Robotics on the Show Floor

(Source: ABI Research)

Key Themes from Automate 2024

Major themes from Automate 2024 can be summarized as follows:

- More General AI versus Generative AI: The centrality of AI in the future of adaptable automation is undoubtedly finding relevance in the current modus operandi in the form of faster, easier robotic programming, object detection, and autonomy. But it is general AI over generative AI that is making a difference today in smart factory automation projects, with many generative AI projects still incubating in an exploratory phase. Prominent examples expected to emerge in 4Q 2024 will focus on speeding the mean time to resolution and lowering deployment costs through guided engineering workflows.

- Many Want to Be “the Switzerland of X”: At least three companies referred to themselves as the “Switzerland of [insert market]” before noon on the first day. On one hand, a little nauseating, and on the other, acknowledging the need for cross-platform orchestration for industrial automation endpoints. Robotic orchestration is one of the best examples because so many factory environments involve a litany of suppliers. Right now, the best Autonomous Mobile Robot (AMR) fleet manager software is made by the same company that makes the AMR. The challenge for cross-platform orchestration is less a technical hurdle and more a matter of competitive market dynamics—every supplier would prefer that users operate in their software environment, and a startup doing a better job would threaten the partners it relies on.

- Software-Defined Automation Is Increasingly Relevant, yet Remains a Leading-Edge Topic Driven by a Few: Products were as prominent as solutions, in many cases, with incumbent industrial automation suppliers including ABB, OTTO (now part of Rockwell Automation), and Zebra offering meaningful advances in software, if only to improve their hardware business. Such a dynamic suggests that many traditional automation companies are willing to innovate to keep up with competition, but are most in tune with where their customers were versus where they are going. The best software-defined automation strategies will support large enterprises, existing automation frameworks, and new cohorts of users both in new markets and at smaller organizations.

- Sustainability Is a Footnote in the U.S. Automation Market: Sustainability did not come through strongly as a theme compared to the European manufacturing shows. However, I’d advise U.S. suppliers to take this chance as the opportunity to lead with respect to sustainability due to its importance to top talent (especially the next generation of workers), relevance in global markets, and likely business impact in terms of supply chain/process optimization. Successful new initiatives must have a business case, in addition to a sustainability case, and must not be the same solution with different messaging.

Figure 3: Siemens on the Show Floor

(Source: ABI Research)

Conclusion

Together, these developments and the show at-large reinforce the need for continuous improvement in the form of innovation to help automation professionals achieve aggressive performance targets. The challenge for suppliers is to deliver operational scale by easing integrations with adjacent and cross-platform factory ecosystems (e.g., the Manufacturing Execution System (MES), Quality Management System (QMS), etc.). Some companies—particularly those with a more open approach—have a better chance than others.

For more content about manufacturing automation, visit ABI Research’s Industrial & Manufacturing Technologies and Industrial & Manufacturing Markets research services.