Today, mobile robots serve as a pillar of the digitization of manufacturing and logistics. As no surprise, Automated Guided Vehicles (AGVs) are at the forefront of modernizing manufacturing and logistics, as they save companies time and money while being highly precise with handling containers, pallets, materials, components, and other important assets. Not to mention, AGVs, like exoskeletons, significantly decrease the risk of workplace injuries.

What Are Automated Guided Vehicles?

Automated guided vehicles are unmanned robots that transport materials and goods within a distribution center, warehouse, seaport, or other work environments involving frequent transportation of heavy assets. AGVs are controlled by a computer and are highly effective at carrying out a repetitive set of instructions. For example, an AGV may be used in an automotive manufacturing plant to continuously deliver materials or components to assembly line workers.

For navigation, AGVs rely on external infrastructure, such as Quick Response (QR) codes or other fiducial markers across the site floor. In this application, AGVs make their way to their intended destination by scanning the markers on the floor and localizing/identifying the correct direction.

Types of Automated Guided Vehicles

The four main types of AGVs are Automated Guided Carts (AGCs), towing AGVs, automated forklifts, and unit load AGVs.

Automated Guided Carts

This variation of AGVs are small robotic vehicles that transport lighter loads compared to other types of AGVs. Because of their easy installation, flexibility, and low cost, AGCs are the most popular choice among AGV adopters.

Tugger AGVs

These are designed from the ground up to support heavy loads, up to 50,000 lbs (22,600 kg). These types of AGVs can also lug multiple carts at the same time, which cuts down on the frequency of trips needed and increases productivity.

Automated Forklifts

Sometimes grouped under AMRs, automated forklifts are unmanned forklifts that lift, transport, and stack materials or goods in the same manner as a human operator. These kinds of AGVs are most commonly found in facilities requiring high rack management.

Unit Load AGVs

Unit load AGVs typically support handling needs in warehouses and production facilities with a powered conveyor or a lift deck. Workers don’t have to touch anything, which makes this variation of AGVs useful when object handling presents a safety hazard (e.g., hazardous material, heavy lifting).

How an AGV Works

Automated guided vehicles are reliant on a pre-determined path to navigate, usually aided by Two-Dimensional (2D) barcodes, magnetic tape on the ground, radio frequencies, sensors, lasers, cameras, a Global Positioning System (GPS), and real-time analytical platforms. These technologies allow for scalable navigation while avoiding collision with surrounding objects and workers in a warehouse, facility, or on dock grounds.

Benefits of Automated Guided Vehicles

The most obvious reason for warehouses and other facilities to invest in automated guided vehicles is the promise of increased productivity. AGVs automate repetitive tasks involving delivering, stacking, and retrieving materials and goods. These robotic systems are trained to execute crucial tasks at a level of efficiency humans cannot replicate.

Similar to industrial exoskeletons, automated guided vehicles also spare human workers the heavy lifting often required in manufacturing and logistics—providing them with more energy to carry out other duties. In a world where workplace injuries cost companies more than US$100 billion per year, AGVs prevent the prevalence of disability payouts to employees who would otherwise strain their backs or other body parts.

Besides increased productivity and keeping workers safe, automated guided vehicles keep labor costs down. Instead of worrying about an employee’s salary, health benefits, 401K, payroll taxes, and absenteeism for a new hire, an AGV is either a one-time purchase or a predictable monthly rental cost, with the occasional maintenance fee. Moreover, the deployment of AGVs in warehousing and production plants can make up for manufacturing labor shortages as they can perform duties like pallet stacking and bringing materials or parts to the assembly line.

"Automated guided vehicles also spare human workers the heavy lifting often required in manufacturing and logistics—providing them with more energy to carry out other duties."

Difference between Automated Guided Vehicles and Autonomous Mobile Robots

Compared to Autonomous Mobile Robots (AMRs), AGVs are much more dependent on programming. The distinction between AGVs and AMRs can be contested, but AMRs do not require external infrastructure to localize themselves and are built with sensors and cameras to self-navigate the warehouse environment. In other words, an AMR is more sophisticated and self-governing than an automated guided vehicle. However, more robust features also bring higher price points, making an AGV more suitable for new adopters of robotics systems.

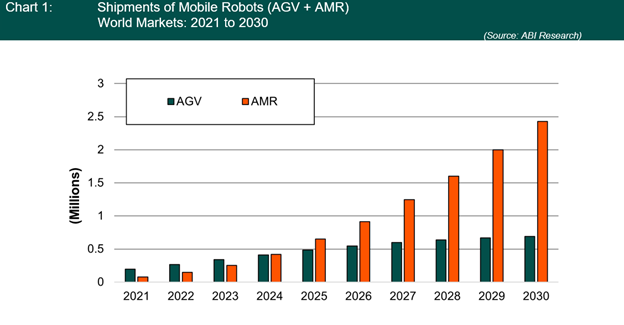

According to ABI Research’s latest Commercial and Industrial Robotics market data report, automated guided vehicles currently account for the majority of mobile robot shipments. However, that trend will change by 2024 when autonomous mobile robots will ship 420,000 units—8,000 more than AGV shipments. By 2030, there will be 2.4 million AMR shipments, while 691,000 AGVs will be shipped. A huge reason for this shift is that new verticals like hospitality and delivery have the desire to do away with external physical infrastructure.

To compare shipments of AGVs with AMRs, reference the chart below.

Considerations

There’s no denying that automated guided vehicles should be embraced, but it’s not wise to rush with an AGV deployment strategy. It’s better to take the time to assess ongoing operations and carefully decide where priorities lie, such as where the biggest bottlenecks occur or which departments need the most help. After thoroughly assessing company needs, it will be easier to choose the right type(s) of automated guided vehicles. From there, scout out vendors that provide the desired solution(s) and the best balance between budget and quality.

To dig deeper into the world of mobile robots like AGVs and AMRs, check out ABI Research’s latest content under the Industrial, Collaborative & Commercial Robotics Research Service.