If you’ve ever walked through a manufacturing plant or a utility site, you can’t help but notice how much is going on. Various equipment and machinery are constantly in use to keep production flowing. To power every one of these processes, industrial companies typically use fossil fuel-based energy sources that generate carbon emissions and harm the planet. To highlight this sustainability challenge, industrial emissions have increased by roughly 70% since the turn of the millennium. Besides the equipment and machinery used in industrial buildings, emissions pile up from the transportation of goods and components along the supply chain as well.

The clock is ticking for industrial companies to adapt and do their part in reaching Net Zero by 2050. ABI Research is at the forefront of analyzing the most effective strategies to decarbonize the industrial sector. In this article, I will share the most promising ways to create a pathway to a decarbonized industrial world using innovative technologies.

Figure 1: Primary Strategies for Industrial Decarbonization

Electrifying Industrial Operations, Equipment, and Fleets

One of the most effective ways to decarbonize industrial operations is by replacing fossil fuels with renewable energy sources. BloombergNEF posits that switching to clean energy may account for half of emissions reductions between 2022 and 2050. Industrial companies can obtain solar, wind, hydroelectricity, and biomass energy through on-site generation or by purchasing agreements such as Power Purchase Agreements (PPAs) and Renewable Energy Credits (RECs).

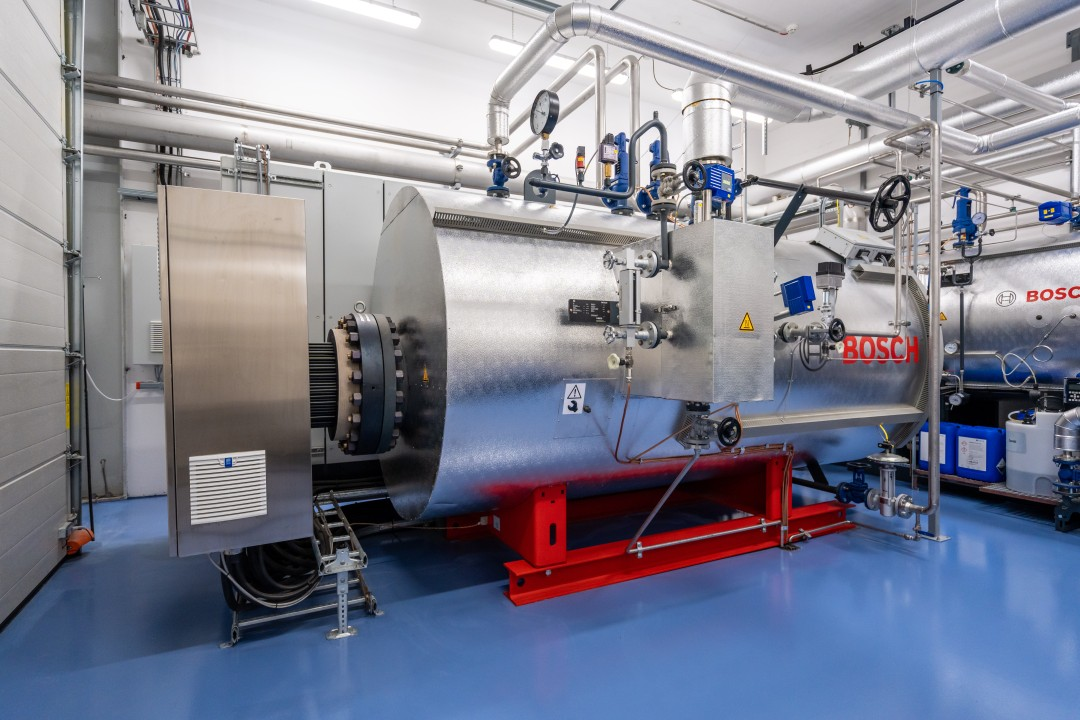

Most industrial equipment used today runs on fossil fuels, which increases carbon emissions. Replacing these machinery and equipment (gas boilers, combustion engines, etc.) with renewable/electric counterparts is another effective Carbon Dioxide (CO2) mitigation tactic. For example, industrial heat pumps that leverage waste heat are about 3X to 5X more energy efficient than gas boilers. Similarly, electric boilers are a more sustainable way to heat water and steam than gas or coal-powered boilers.

Figure 2: Bosch Electric Steam Boiler

The final piece of the industrial electrification puzzle is the transition to Electric Vehicle (EV) supply chain fleets. In some cases, particularly in the European Union (EU), the government mandates industrials to reduce fleet emissions. This has spurred companies like Schneider Electric to invest in EV fleets and charging infrastructure.

Read More:

The Future of Industrial Decarbonization: 8 Data-Backed Trends from ABI Research’s Latest Forecast

Charting an Unbeatable Fleet Electrification Strategy for Managers and Solution Providers

Getting the Most Out of Your Energy Sources

Digital technologies are another key decarbonization area, projected to reduce emissions by 20% by 2050. Adopting these technologies could result in 5% to 10% emissions reduction for industries today. Technologies like Artificial Intelligence (AI)/Machine Learning (ML) and digital twins minimize emissions and waste through energy and material efficiencies. Furthermore, these technologies inform industrial companies where energy savings opportunities exist within operations. Industrials can also leverage Internet of Things (IoT)-enabled devices and smart sensors to monitor energy consumption in real time.

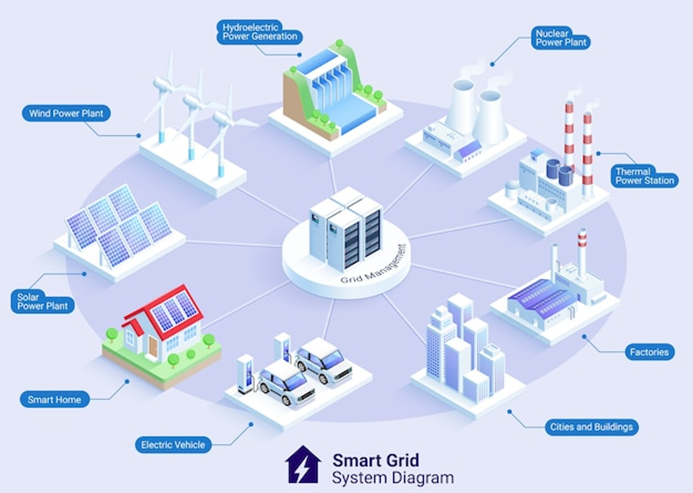

These digital technologies are integral to the development of smart grids. Smart grids leverage these technologies to forecast future energy demand, allocate renewable energy resources optimally, stabilize the grid, and manage multiple energy types.

Energy-efficient technologies are also key to reducing demand for energy and inducing cost savings for industrial companies. Deploying energy storage systems is a standout strategy, providing a reliable way to harness solar and wind energy when the sun isn’t shining and the wind isn’t blowing. The fluctuating nature of renewable energy availability is a key challenge in industrial decarbonization. Solutions like Battery Energy Storage Systems (BESSs) store clean energy during peak times and allow companies to use it later during off-peak times. Energy storage systems ensure renewable energy demand and supply always match, the grid is stabilized, operations are sustained, and fossil fuel production is minimized.

Figure 3: Smart Grid System Diagram

Green Hydrogen and Biofuels Serve As Sustainable Energy Alternatives

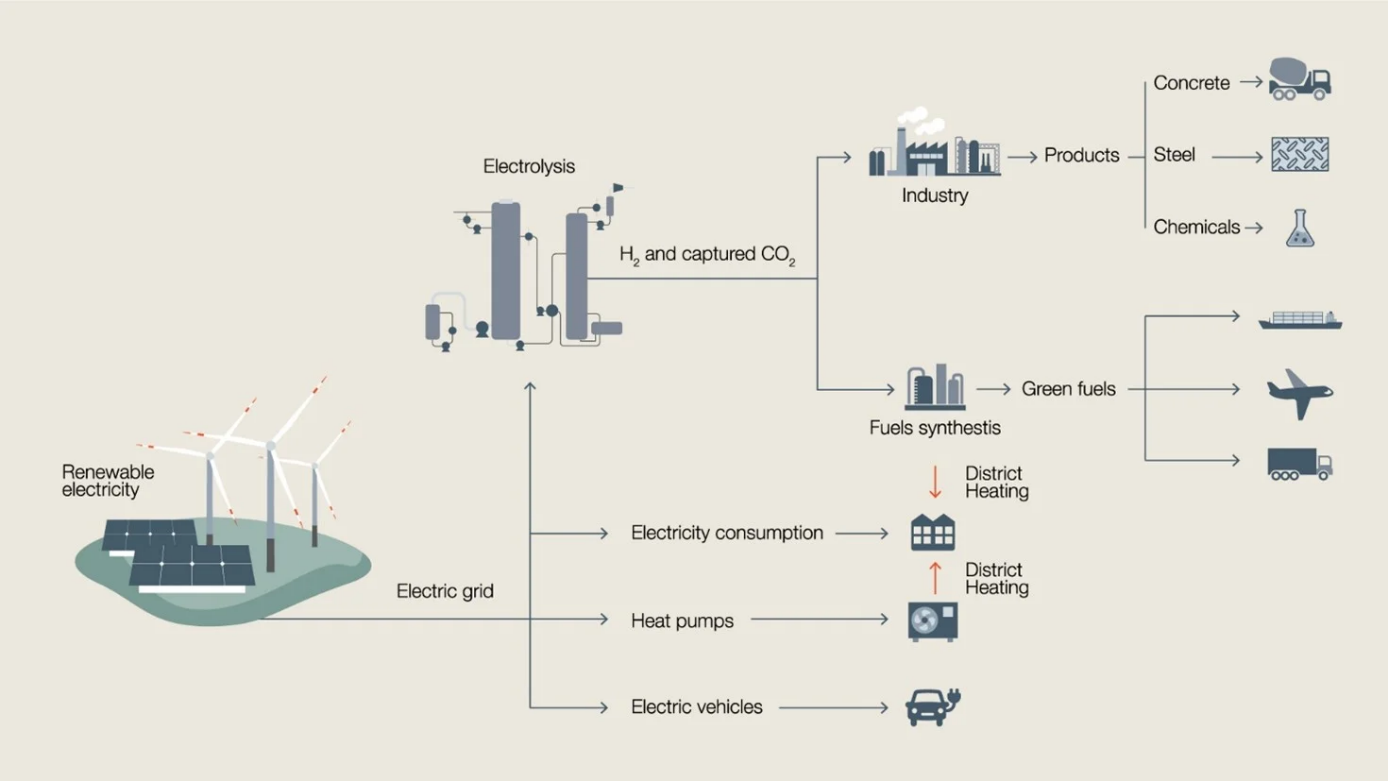

Full electrification of industrial operations is deemed unattainable across some sectors and regions, making the use of low-carbon fuels an increasingly popular decarbonization strategy. Hydrogen is a more sustainable energy source option than fossil fuels and can even be 100% clean when produced from renewable sources, known as green hydrogen. It is highly versatile and can be converted into electricity or used as feedstock for industrial, commercial, and mobility use cases. Although more expensive, green hydrogen is a crucial decarbonization technology for high-temperature processes that are not well-suited for electrification.

Another way green hydrogen promotes sustainable industrial operations is through energy storage. If more renewable energy is generated than needed, the excess energy can be used later for electricity.

Some of the main industrial use cases of green hydrogen include:

- Developing hydrogen fuel cells for EVs

- A fuel source for multiple transportation methods, including mining vehicles, aviation, trains, and maritime

- Feedstock for manufacturing ammonia and fertilizers in the chemical industry

- Feedstock for producing green steel

- Fuel for reducing emissions and clinker requirements in cement production

Figure 4: Technology Pillars and Use Cases of Green Hydrogen

Besides green hydrogen, biofuels are also gaining prominence in industrial decarbonization efforts. According to the International Energy Agency (IEA), biofuel demand increased by 6% in 2022. While the agricultural and transport sectors are the biggest beneficiaries of biofuels, there is strong potential to reduce Greenhouse Gas (GHG) emissions with biofuels in the industrial space. Renewable diesel, which can be 75% more energy efficient than petroleum diesel, is the most promising biofuel solution for industrials. Companies in the mining and oil & gas industries can fuel their mining vehicles, mining equipment, and drill rigs with 100% renewable diesel. Conveniently, petroleum diesel can be replaced with renewable diesel without any engine alterations required.

Re-Purposing CO2 Emissions for Future Industrial Processes

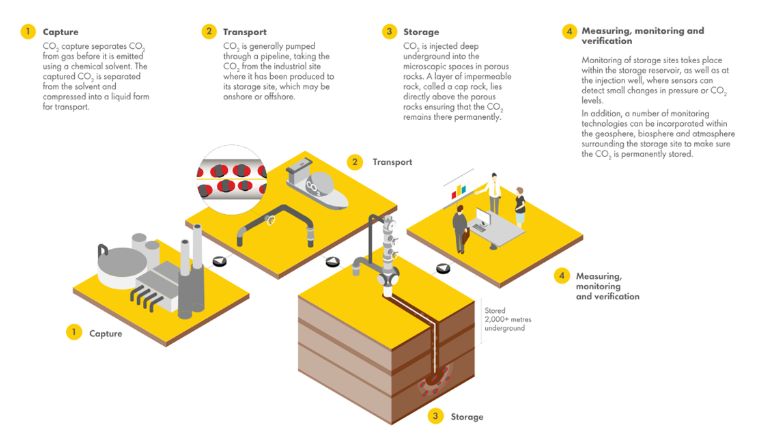

Although the least commonly used decarbonization strategy, Carbon Capture, Utilization, and Storage (CCUS), has immense potential to reduce emissions across industries. CCUS technologies capture carbon emissions from industrial processes and then reuse them for future processes. Alternatively, CO2 emissions can be stored in large underground formations. This process essentially recycles carbon emissions, resulting in a sharp decline in emissions generation.

In industries where achieving net zero is especially challenging, such as the steel, cement, and oil & gas sectors, CCUS will be paramount. There are about 40 commercial facilities using CCUS solutions worldwide, signaling a lack of awareness of and buy-in for the technology. Most projects are still in the early pilot stages and the costs are high, making the business case for CCUS investment more difficult to justify as an industrial decision-maker. Therefore, billions or even trillions of more dollars must be invested in CCUS technologies throughout the decade before a Return on Investment (ROI) is demonstrable and adoption becomes more widespread. Moreover, my team and I foresee CO2 transportation and storage challenges hindering the short-term potential of CCUS.

Figure 5: Schematic of CCUS

Decarbonizing Critical Industries

The steel, cement, mining, and oil & gas industries are some of the most critical industries in the world. Companies in these sectors are essential in building infrastructure and providing the resources we need to keep society afloat. However, these also happen to be some of the highest emission-generating industries. We’re now presented with a complex dilemma: how can we ensure the continuity of these essential industrial operations, while minimizing the carbon footprint?

Learn more about the strategies these industries can use to decarbonize their operations, as well as some notable technology vendors helping make that happen by downloading ABI Research’s Decarbonization Technologies for Industries report. This content is part of the company’s Sustainability For Industrial Markets Research Service.